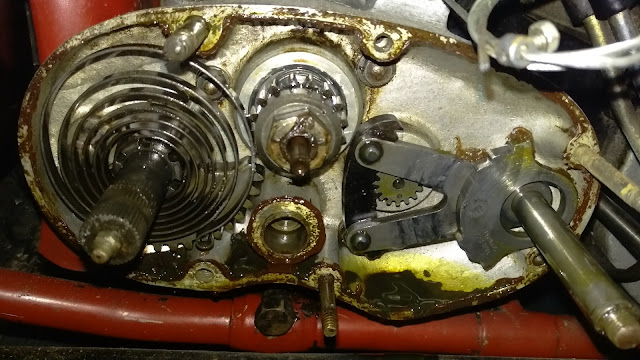

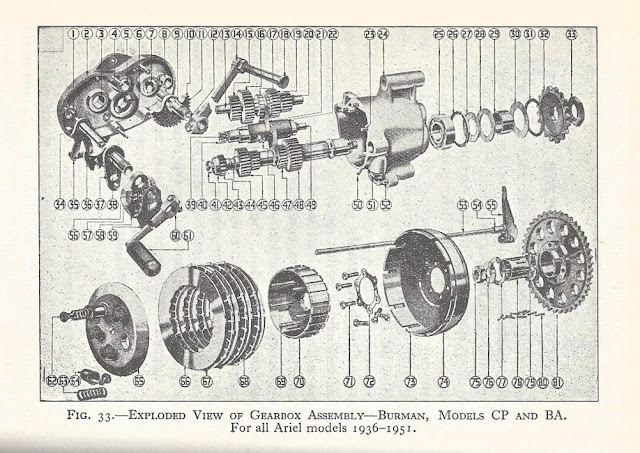

Now we know what we have to do, we can get started with the rebuild helped by these lovely new bushes from Geoff at AOMCC Gearbox Spares

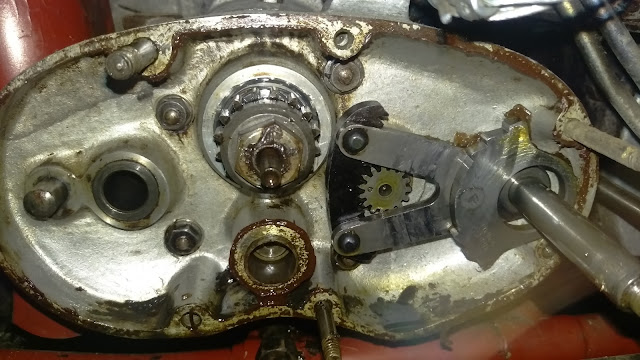

First job is to remove the two Welch plugs over the layshaft and camshaft; I drill a hole in these and lever them out:

We'll fix the camshaft end float with this 0.3 mm shim. It's a commercially available 26 mm ID shim that I've opened out to fit:

A trial fit, with shakeproof washers under the BSW nuts (to prevent them coming loose) revealed the shim problem. I went through two bags of shims with a micrometer and found that all the shims in the 0.5 mm bag were 0.3 mm and all the ones in the 0.3 mm bag were 0.5 mm...

Easily found and fixed, fortunately. It pays to measure and test at every step.

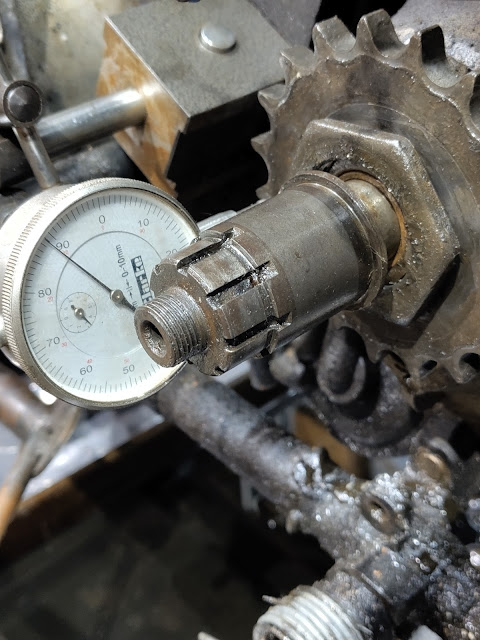

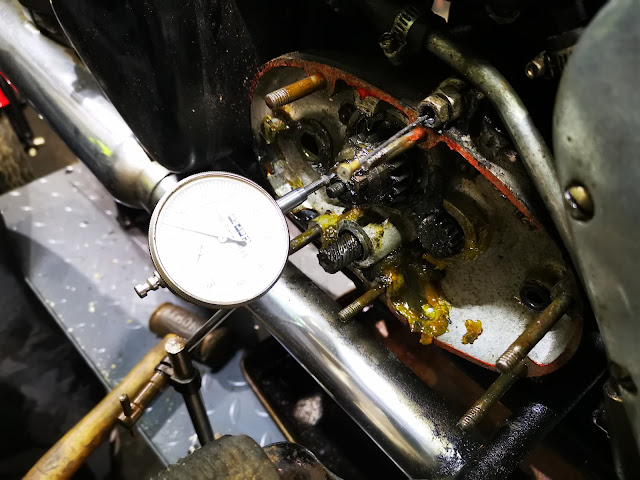

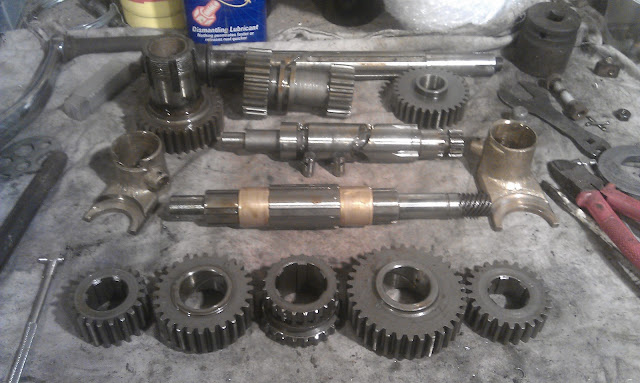

With that fixed and the selector shaft showing about 0.05 - 0.07 mm (2 thou or so) end float we can set up to measure the mainshaft and sleeve gear end floats.

The mainshaft endfloat still measures 0.88 mm or 35 thou: not surprising, since we haven't changed anything.

The sleeve gear shows 1.11 mm when in top gear:

A call to AOMCC gearbox guru Geoff suggested I make a spacer to reduce that to 0.11 mm, 4 thou, to maximise spline engagement. Geoff provided a useful spacer to make that from:

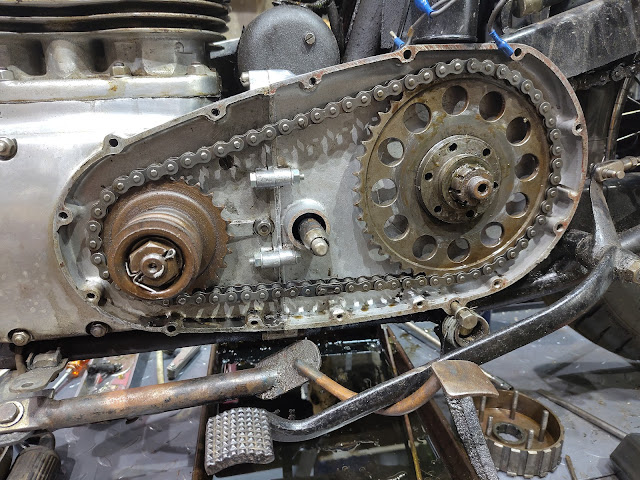

This is the spacer that sits under the gearbox sprocket, inside the oil seal. It parts off quite easily on the mini-lathe, once you remember that you don't want the lathe in high gear!

Reassembling the gearbox reveals sleeve gear movement at 0.8 mm; I must have measured that wrongly as I thought I had 1.11 mm and added a 0.75 mm spacer. Mainshaft end float is now 0.6 mm, down from 0.88 mm and around 25 thou. This is 1/40", within Ariel's stipulated range of 1/64" - 1/32".

All good news; however, since tightening the inner case nuts for what I thought was the last time, I've realised that the camshaft is too tight. It turns, but that 2 thou end float has clearly been taken up by gasket compression - I may relieve the bush a little or I may fit shims to 0.2 mm (8 thou) rather than the 0.3 mm currently fitted (12 thou) which should give me what I need.

As it turned out, smoothing the surface of the camshaft bush was all that was required to return to normal operation, so I tightened up the end cover. The last step was to fit the two Welch plugs, which have to be done before the sprocket goes on for the last time. It would have paid to ensure the bores for these were clean before the bushes went in, as enthusiastic staking at the factory had left a lot of material in the layshaft bush bore which had to be scraped out with a twist drill ground flat, like an end mill.

More next time.