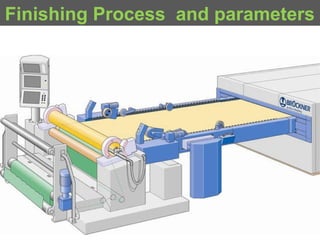

Finishing process and parameters

- 1. Finishing Process and parameters

- 2. Prepared By : Mazadul Hasan sheshir ID: 2010000400008 13th Batch (session 2009-2013) Department : Wet Processing Technology Email: [email protected] Blog : www. Textilelab.blogspot.com (visit) Southeast University Department Of Textile Engineering I/A 251,252 Tejgaon Dhaka Bangladesh Prepared By :

- 3. “Study An Effective And Consistent Finishing Effect Through Stabilizing Dryer on Knit Fabric“

- 4. Total Textile Process at a Glance

- 5. Introduction Here we’ve presented the project on the topic of finishing of textile. We’ve tried our best to include all the important term related to textile finishing. I hope we could know some important parameter and suggestion on textile finishing.

- 6. Objectives of this Project: The objects of this project is to study an effective and consistent finishing effects through stabilizing dryer on knit fabric. To study about assistant device that improve quality, effect and production. To improve crease mark, hand feel, appearance, smoothness, shrinkages etc

- 7. Knit fabric Finishing The term finishing, in a broad sense it covers all the processes of making the fabric good looking, good hand feeling, luster and of course for buyer requirement. It is done after dying and before delivery to market. Various types of parameters are controlled during finishing section considering buyer requirement. The term also includes bleaching, dyeing, mercerizing etc. But normally the term is restricted to the final stage in the sequence of treatment of Knit fabrics after bleaching and dyeing. However, fabrics which are neither bleached nor dyed are also finished.

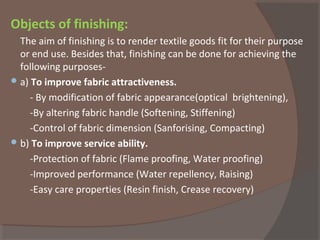

- 8. Objects of finishing: The aim of finishing is to render textile goods fit for their purpose or end use. Besides that, finishing can be done for achieving the following purposes- a) To improve fabric attractiveness. - By modification of fabric appearance(optical brightening), -By altering fabric handle (Softening, Stiffening) -Control of fabric dimension (Sanforising, Compacting) b) To improve service ability. -Protection of fabric (Flame proofing, Water proofing) -Improved performance (Water repellency, Raising) -Easy care properties (Resin finish, Crease recovery)

- 9. Types of finishing: 1) Chemical finishing: Softener, Biopolishing, Enzyme, UV Protection, Anticreaase, Silicon Finish etc. 2) Mechanical finishing: Shrinkage, Raising and Shearing,

- 10. Finishing effects: Easy - care Crease recovery. Dimensional stability. Good abrasion resistance. Improved tear strength. Good sew ability Soft or stiff hand feel Shine or luster

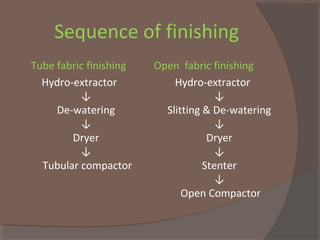

- 11. Sequence of finishing Tube fabric finishing Hydro-extractor ↓ De-watering ↓ Dryer ↓ Tubular compactor Open fabric finishing Hydro-extractor ↓ Slitting & De-watering ↓ Dryer ↓ Stenter ↓ Open Compactor

- 12. Observation of Different Finishing m/c:

- 13. Slitting machine: This machine is used to make the tube fabric into open form. Machine parts and functions: Rotary blade: To cut the fabric through break wales line Ring: To help cutting Guide Roller: To guide the fabric to plaiting Plaiting: To plate the fabric Sensor: sense for cutting through break wales line

- 15. Tube Squeezer or De-Watering M/C After dyeing process fabrics are sent for de- watering. This is the process to remove the water from the fabric partially by squeezing. This is the main function of the squeezing machine. Important parts -Twist detector -Expander -Padder

- 16. The basic function of the squeezing m/c: -To remove the water from the fabric. -To control the width of the fabric. -To control the length of the fabric. -To control the spirality of the fabric. -To control the over feeding system. -To increase the softness of the fabric. -To remove the crease mark of the fabric.

- 17. Dryer m/c: Dryer machine is used to dry the fabric with the help of the steam. Besides drying it controls the shrinkage and prepares the fabric for the next process. Types of Dryer : Gas Dryer Stem Dryer The basic function of the dryer: To dry the fabric. To control the over feed system (Shrinkage control) To control the GSM of the fabric.

- 18. Important Parts of dryer m/c: Conveyor net Chamber Burner Exhaust air fan Over feed roller Filter net Fan Nozzle

- 19. Stenter machine: Stenter machine is very important for finishing knit fabric in open form. It can be used for the following functions: Heat setting is done by the stenter for lycra fabric, synthetic and blended fabric. Skew and bow are controlled through stenter. Finishing chemical apply on fabric by the stenter. Loop of the knit fabric is controlled. GSM, Dia, Spirality, Shrinkage, Moisture of the fabric is controlled by stenter. Fabric is dried by the stentering process. Curing treatment for resin, water repellent fabric is done by the stenter.

- 20. picture of stenter m/c:

- 21. Parts of Stenter Machine: Padders Weft straighter (Mahlo) Burners 10 Heat recovery Attraction rollers Circulating fans 10,8 Exhaust fans 2 Winder 2 Clips Pins I.R Cooling drums 2

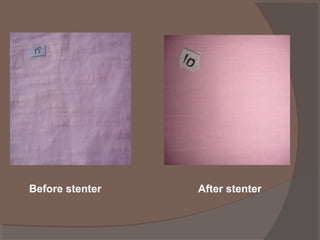

- 22. Before stenter After stenter

- 23. Finishing effect of stenter m/c Before stenter After stenter Water is contained in fabric Spirality is appeared Shrink is appeared GSM is not adjusted GSM:- (140-145) Fabric dia is uncontrolled Water is removed Spirality is not appeared Shrink is controlled GSM isn't adjusted GSM:- (155-160) Fabric dia is controlled

- 24. There are some faults found in stenter machine for specially S/j fabrics: GSM control Skewing & Bowing Spirality Dimensional stability

- 25. Suggestions: If mahalo/ plevia device is stetted with stenter this problem can be solved. This device improves quality, effect and production by following ways: •Skew control •Bow control •Even input in stenter •Man power reduction •Use sensor for even temperature, even pressure, even steam, reduction fuel for producing steam or hot air.

- 27. COMPACTOR MACHINE: Compactor is a textile finishing machine which is designed specially for compacting 100% cotton knitted fabric like jersey, pique, interlock & rib etc. as well as cotton blended fabric in rope form

- 28. The basic functions of the Tube compactor m/c: Tube compactor is used to finish knit fabric in tube form To control the GSM. (Increase & decrease). To control dia. To control the shrinkage. (Increase & decrease). Functions of the Open Compactor m/c: To compact the fabric in open form To control the GSM. (Increase & decrease). To control the dia. To control the shrinkage. (Increase & decrease).

- 29. Important parts Overfeed roller Expander Blanket Steam sprayers Cylinder Teflon covers

- 30. Special note on compactor finishing: In case of light color padder pressure should be low. Otherwise shade will be lighter. If the padder is not clean, then line mark can appear in the fabric. Fabric dia, extension, speed, compaction & overfeed will vary depending on the fabric type and finishing requirements. In the case of low GSM S/J fabric padder pressure and speed will be maximum. In the case of high GSM S/J fabric then padder pressure and speed will be minimum. In case of Lycra single jersey fabric, speed & padder pressure will be minimum.

- 31. Before Compactor After Compactor

- 32. Finishing effect of Compactor m/c Before Compactor Finishing After Compactor Finishing Small amount of water is contained. Crease mark Luster medium Hand feel medium GSM isn’t adjusted Shrinkage is high Access water is removed. Low GSM can be adjusted. Crease mark isn’t appeared Luster medium Hand feel good GSM is adjusted Shrinkage is removed

- 33. Problem of compactor m/c: Hand feel may be not good Shrinkage problem Low GSM Width may be not adjusted Remedies of problem: Sunforising device can solve this problem. This device can easily control of low GSM fabric. About 10 GSM can be controlled . Dimensional stability can be also controlled.

- 34. Brio machine: It is one of the latest finishing m/c in textile. It can be used in stead of Tumble dryer. It can finish of textile material without any change of fabric appearance. Function of Brio machine: To dry evenly It makes good appearance of fabric. To control the GSM To remove crease mark Significant luster improve To create finishing effect by vibration Ideal for decorative and sensitive fabric

- 36. Before Brio After Brio

- 37. Before Brio After Brio

- 38. Finishing effect of Brio m/c: Before Brio Finishing After Brio Finishing Crease marks are appeared Luster is not good Medium appearance Hand feel is not good GSM isn’t adjusted Crease marks are not appeared Luster is good Very good appearance Hand feel is good GSM is adjusted

- 39. Graphical view of 140GSM s/j fabric spirality %. (Before Brio Process) S/No Spirility % 1 12.39% 2 8.88% 3 7.9% 4 10.5%

- 40. Graphical view of spirality %.(After Brio Process) S/ No spirility% 1 2.5% 2 5% 3 1% 4 1.33%

- 41. Graphical veiw shrinkage %.

- 42. Ultra-soft m/c: Ultra soft machine is used to increase softness of fabric. This is a mechanical process of finishing. Note: If speed of carbon brush is high then softness will be high Softening action is done on the face side of the fabric. At least 5% GSM of the fabric will reduce after brushing. Dust storage unit is present. Dia of the fabric will reduce after brushing (ex-20%) and thus fabric must run to the stenter m/c after brushing.

- 43. Brushing Machine By the brushing machine back side of the fleece fabric is brushed. Note: Brushing action is done on the back side of the fleece fabric Fabric is run in m/c for 3-6 times until the target is achieved. fabric GSM will reduce. This is a mechanical action and once produced cannot be changed.

- 44. Before brush After brush

- 45. Conclusion: In this project, different important factors are discussed on knit fabric finishing that can impact on finishing. All the reports are done by practical knowledge from different industry and finally some important factors which are obtained from knitting to dyeing and finishing. So deviations are obtained and the reason of the problem must observe to avoid in further. Because customers are always worried about the product quality. We hope this project work will be very helpful in our practical industrial life.

- 49. 1. Yarn Manufacturing Technology Link : http://www.facebook.com/pages/Yarn-Manufacturing- Technology/485014954866808 2. Fabric Manufacturing Technology Link : http://www.facebook.com/pages/Fabric-Manufacturing- Technology/459520217425605 3. Garments Manufacturing Technology Link : http://www.facebook.com/pages/Garments-Manufacturing- Technology/472364799463126 3. Wet processing Technology Link : http://www.facebook.com/pages/Wet-Processing-Technology- Dyeing-/468645219825404 4. Fashion-Design-and-Technology Link : http://www.facebook.com/pages/Fashion-Design-and- Technology/587655294583875?ref=ts&fref=ts My Facebook Textile related Pages http://www.textilelab.blogspot.com (Visit My Blog for more Info )