This presentation contains details on the topic 'Food Irradiation'.

It contains the following topics:

Introduction to Food Irradiation

Dose and Dosimetry

Principle of Food Irradiation

Instrument Used in Food Irradiation

Food Irradiation Facilities- Gamma Rays, Electron Beam and X-Ray Facility

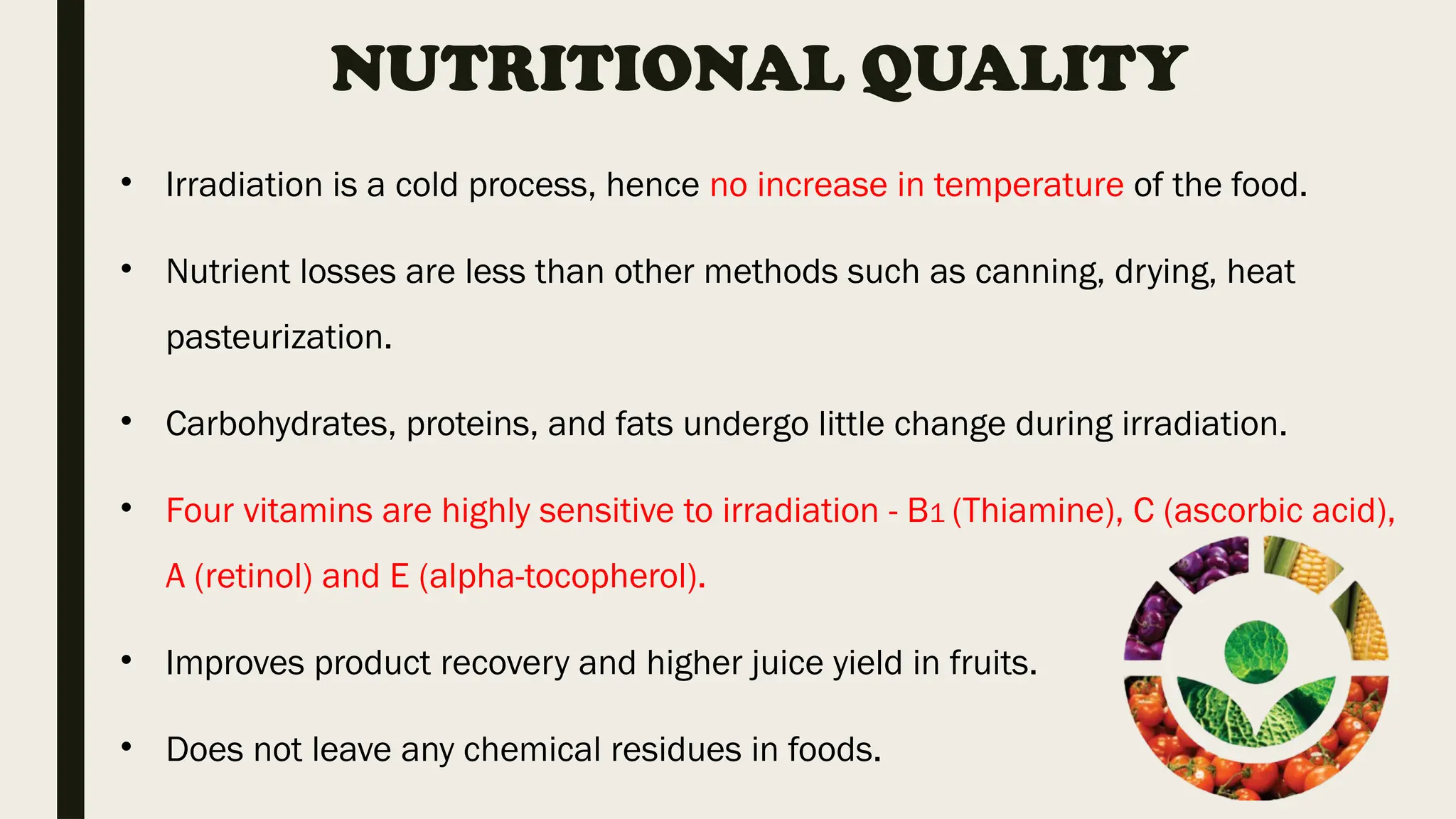

Nutritional Quality of Irradiated Foods

Applications of Food Irradiation

Types of Food Irradiation - Radurization, Radicidation and Radappertization

Advantages of Food Irradiation

Disadvantages of Food Irradiation