OSHA Hazard Communication and Global Harmonization System (GHS)

- 1. Adapted from the Michigan Occupational Safety & Health Administration

- 2. Overview OSHA has issued a final rule to revise 29 CFR 1910.1200 – the Hazard Communication Standard (HazCom) Goal is to integrate components of the United Nation’s (UN) Global Harmonization Standard (GHS) into HazCom Rule modifies Material Safety Data Sheet (MSDS) requirements, labeling, classifications, and requires retraining of all employees.

- 3. Why the Change to Haz Com? To align with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) adopted by 67 nations To provide a common and consistent approach to classifying chemicals • Reduce confusion and improve understanding of the hazards • Facilitate training • Help address literacy problems

- 4. Intent To provide employees with information to help them make knowledgeable decisions about chemical hazards in their workplace

- 5. Who is Affected by Changes? Manufacturers, Distributors, Importers Change SDS information and format Change container labeling Employers Training employees on changes to: SDS (new 16-section format) Container Labels Employees Recognize and understand hazards: Information in new SDS format Pictograms on container labels Precautionary and hazard statements

- 6. Effective Dates and Requirements Effective Completion Date Requirement(s) Responsible Party December 1, 2013 Train employees on the new label elements and SDS format Employers June 1, 2015 Compliance with all modified provisions of the final rule except: Chemical manufacturers, importers, distributors, and employers December 1, 2015 The distributor shall not ship containers labeled by the chemical manufacturer or importer unless it is a GHS label Distributor June 1, 2016 Update alternative workplace labeling and hazard communication program as necessary, and provide additional employee training for newly identified hazards Employer Transition Period: 12/2012 to the effective completion dates noted above May comply with either MIOSHA Part 42, 92 and 430 (final standard), or the current standard, or both Chemical manufacturers, importers, distributors, and employers Source: MIOSHA

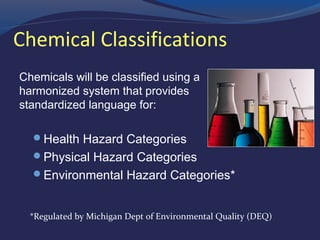

- 7. Chemical Classifications Chemicals will be classified using a harmonized system that provides standardized language for: Health Hazard Categories Physical Hazard Categories Environmental Hazard Categories* *Regulated by Michigan Dept of Environmental Quality (DEQ)

- 8. Chemical Classifications: Health Hazards Hazard Class Hazard Category Acute toxicity 1 2 3 4 Skin Corrosion/Irritation 1A 1B 1C 2 Serious Eye Damage/Eye Irritation 1 2A 2B Respiratory or Skin Sensitization 1 Germ Cell Mutagenicity 1A 1B 2 Carcinogenicity 1A 1B 2 Reproductive Toxicity 1A 1B 2 Lactation Specific Target Organ Toxicity – Single Exposure 1 2 3 Specific Target Organ Toxicity – Repeated Exposure 1 2 Aspiration 1 Simple Asphyxiants Single Category Most Severe Hazard Category 1 Slightly Hazardous Category 4

- 9. Health Hazard Rankings GHS ranks health hazards differently than the National Fire Protection Agency (NFPA) and Hazardous Materials Information System (HMIS) GHS ranks Health Hazard Category 1 as the most hazardous with Category 5 as the least hazardous NFPA/HMIS health hazard rating system ranks health hazards in the opposite direction with 4 being the most hazardous Know the difference! NFPA System

- 11. Chemical Classifications: Health Hazards 10 Health Hazard Classifications Acute Toxicity Skin Corrosion/Irritation Respiratory or Skin Sensitization Germ Cell Mutagenicity Carcinogenicity Reproductive Toxicity Specific Target Organ Toxicity – Single Exposure Specific Target Organ Toxicity – Repeated Exposure Aspiration Simple Asphyxiants

- 12. Chemical Classifications: Physical Hazards Explosives Flammables Aerosols Oxidizers Compressed Gases Self-Reactive Chemicals Pyrophorics Self-heating Chemicals Chemicals, which in contact with water, emit flammable gases

- 13. Chemical Classifications: Physical Hazards Hazard Class Hazard Category Explosives Unstable Explosives Div 1.1 Div 1.2 Div 1.3 Div 1.4 Div 1.5 Div 1.6 Flammable Gases 1 2 Flammable Aerosols 1 2 Oxidizing Gases 1 Gases under Pressure Compressed gases Liquefied gases Refrigerated liquefied gases Dissolved gases 1 Flammable Liquids 1 2 3 4 Flammable Solids 1 2 Self-Reactive Chemicals Type A Type B Type C Type D Type E Type F Type G Pyrophoric Liquids 1 Pyrophoric Solids 1 Pyrophoric Gases Single Category Self-Heating Chemicals 1 2 Chemicals in which contact with water emit flammable gases 1 2 3 Oxidizing Liquids 1 2 3 Oxidizing Solids 1 2 3 Organic Peroxides Type A Type B Type C Type D Type E Type F Type G Corrosive to Metals 1 Combustible Dust Single Category Higher Hazard Lower Hazard

- 14. Labels This style will appear on product labels beginning no later than June 1, 2015. New Label Elements: Symbols called “Pictograms” Signal Words Hazard Statements Precautionary Statements Product Identification Supplier/Manufacturer Identification www.osha.gov/Publications/HazComm_QuickCard_Labels.html

- 15. Label Pictograms There are 9 pictograms. Only 8 are regulated by MIOSHA Health Hazards Physical Hazards Environmental Hazards (Regulated by DEQ) DEQ

- 16. Labels: Pictograms – Health Hazards • Acute toxicity (Less Severe): • Irritant • Dermal sensitizer • Acute toxicity (harmful) • Narcotic effects • Respiratory tract irritation • Acute toxicity (Severe)

- 17. Labels: Pictograms – Health Hazards • Skin corrosion • Serious eye damage/ • Eye irritation • Carcinogen • Respiratory sensitizer • Reproductive toxicity • Target organ toxicity • Mutagenicity • Aspiration Hazard

- 18. Labels: Pictograms – Physical Hazards • Flammables • Self reactives • Pyrophorics • Self heating • Emits flammable gas • Organic peroxides • Explosives • Self reactives • Organic peroxides

- 19. Labels: Pictograms – Physical Hazards Corrosive to Metals Gases under Pressure Oxidizer

- 20. Labels: Signal Word These are words used to indicate the severity of the hazard and alert employees to the potential hazard. There are two signal words. Only one of these words will appear on the chemical label: “DANGER”(more severe hazard) “WARNING” (less severe hazard) Not all labels will have a signal word. Some chemicals are not hazardous enough to require that a signal word appear on the label.

- 21. Labels: Hazard Statement There are specific hazard statements that must appear on the label based on the chemical hazard classification. Examples: Flammable liquid and vapor Causes skin irritation May cause cancer

- 22. Labels: Precautionary Statements Precautionary statements describe recommended measures that should be taken to protect against hazardous exposures, or improper storage or handling of a chemical. Examples: Wear respiratory protection Wash with soap and water Store in a well ventilated place Not necessarily a mandate for employees to follow.

- 23. Labels: Identification Product identification (i.e. name of product) Supplier identification: Address Telephone number

- 24. Labels: Other or Supplemental Information Other information that may be included on the label: Physical state Color Hazards not otherwise classified Route of exposure Storage and disposal Hazard prevention and emergency response instruction

- 26. Safety Data Sheets (SDS) Under the new Hazard Communications Standard, Material Safety Data Sheets (MSDS) are now called Safety Data Sheets (SDS). All SDSs will have a standardized 16-section format. Ex: First Aid in Section 4 Employers must ensure that SDSs are readily accessible to employees. Safety Data Sheets

- 27. Safety Data Sheet Sections Section 1 – Identification Section 2 – Hazard(s) Identification Section 3 – Composition / Info on Ingredients Section 4 – First-aid Measures Section 5 – Fire-fighting Measures Section 6 – Accidental Release Measures

- 28. Safety Data Sheet Sections Section 7 – Handling and Storage Section 8 – Exposure Controls / Personal Protection Section 9 – Physical and Chemical Properties Section 10 – Stability and Reactivity Section 11 – Toxicological Information

- 29. Safety Data Sheet Sections Section 12 – Ecological Information* Section 13 – Disposal Consideration* Section 14 – Transport Information* Section 15 – Regulatory Information* Section 16 – Other information including date of preparation of last revision *Sections outside of MIOSHA jurisdiction but these sections must be included for a GHS compliant SDS.

- 30. Revised Posters – MSDS to SDS

- 31. 31 OSHA’s HazCom Standard Purpose: To ensure that employees know about the hazards of the chemicals in their workplace, including how to protect themselves from exposures and reduce the risk of illnesses and injuries related to hazardous chemicals. The major components are: Written Hazard Communication Program Container Labeling Safety Data Sheets (SDSs)

- 32. Employer’s Written Hazard Communication (HazCom) Plan Must be available to all affected employees Describes container labeling, SDSs, and employee training for each workplace List of the hazardous chemicals Make information regarding hazards and protective measures available to other employers onsite WSU’s Hazard Communication Plan: www.oehs.wayne.edu/training/right-toknow.php

- 33. Hazard Definition and Terms Routes of Entry Chemicals may enter the body in four ways: 1. Inhalation (breathing) 2. Ingestion (swallowing) 3. Absorption through the skin 4. Injection

- 34. Hazard Definitions & Terms Dose: The amount of material an individual is exposed to. Dose effects: Depend on the concentration of material over a period of time. Acute effects: Occur rapidly as a result of short- term exposures, and are of short duration. Chronic effects: Occur as a result of long-term exposure, and are of long duration.

- 35. What Training is Needed? Explanation of the HazCom program, including information on labels, SDSs, and how to obtain and use available hazard information Hazards of chemicals Protective measures such as engineering controls, work practices, and the use of personal protective equipment (PPE) How to detect the presence or release of a hazardous chemical (using monitoring devices, observation, or smell)

- 36. Employee Training must be complete by 12/01/2013 Details of the facility specific hazard communication program: Location and availability of written program and SDSs Physical hazards, health hazards, and any additional hazards of the chemicals in the work area Chemical list, location and use of hazardous chemicals Secondary container labeling system SOPs to protect employees from the chemical hazards Methods used to detect the presence or release of hazardous chemicals (sensor alarms, odors, visual, monitoring devices)

- 37. Training Quiz You’re almost finished! To complete this training, click on the link below to take a brief quiz and give us your contact information: OSHA Hazard Communication Standard and the Global Harmonization System (GHS) Quiz Take the quiz

Editor's Notes

- #4: Since 1992, the United Nations have been working to create and enhance a globally harmonized system for the classification and labeling of chemicals that can be used by importers, distributers and manufacturers worldwide.

- #8: Chemicals must now go through a specific, prescriptive classification process to determine which hazards are present and which hazard and precautionary statements apply. This can be a lengthy process. Environmental Hazards are not regulated by MIOSHA.

- #9: This chart shows the new health hazard classes and the hazard categories that correspond to each of the health hazard classes. Hazard category 1 (or column furthest to the left) is the most hazardous. Hazard categories become less severe as you move to the right in the chart. Manufacturers, importers and distributers must classify all hazards for their products. GHS health hazards are ranked the opposite of the NFPA/HMIS System. GHS ranks 1 as the most hazardous. NFPA ranks 4 as the most hazardous.

- #14: This chart shows the physical hazard classes and the hazard categories that correspond to each of the physical hazard classes. Hazard category 1 (or column furthest to the left) is the most hazardous. Hazard categories become less severe as you move to the right in the chart. Manufacturers, importers and distributers must classify all hazards for their products.

- #15: This is an example of the new label style that is to appear on product labels beginning no later than June 1, 2015.

- #20: *Note that the corrosive pictogram used to designate corrosion to metal is the same pictogram used for skin corrosion/serious eye damage/eye irritation under the health hazard classification. Not all health hazards represented by this pictogram are corrosive to metal so it is important to look for additional information on the label and in the SDS. Oxidizers are chemicals that can emit oxygen and increase the risk of fire.

- #21: In the past, there have been several signal words that may have been used to indicate a hazard like caution, warning, danger. The GHS permits the use of only 2 signal words: “Danger” and “Warning”. Only 1 of the signal words is permitted to appear on the label based on the classification of the chemical.

- #22: Definition of Hazard Statement: "Hazard statement" means a statement assigned to a hazard class and category that describes the nature of the hazard(s) of a chemical, including, where appropriate, the degree of hazard. Manufacturers, importers and distributers use the classification system outlined in GHS to identify which statements must appear in the SDS and on the label found in Appendix C.

- #23: Definition of precautionary statement: "Precautionary statement" means a phrase that describes recommended measures that should be taken to minimize or prevent adverse effects resulting from exposure to a hazardous chemical, or improper storage or handling. The employer is to evaluate the precautionary statements to determine if these need to be followed by employees. This decision may be based on several factors: How chemical used Where it is used (ventilation concerns) How much of the chemical is used (quantity) Air sampling or testing results (permissible exposure limits) How long the chemical is used (time) Other considerations For example: A precautionary statement may state “Wear respiratory protection”; however, employees may not be required to wear a respirator based on the employer’s evaluation of the factors listed above (how, where, how much, time, pel).

- #24: Definition of product identifier: "Product identifier" means the name or number used for a hazardous chemical on a label or in the SDS. It provides a unique means by which the user can identify the chemical. The product identifier used shall permit cross-references to be made among the list of hazardous chemicals required in the written hazard communication program, the label and the SDS.

- #25: This is discretionary or supplemental information that may be provided by the manufacturer, importer or distributer. This information is not required to be on the label; however it will be found in the SDS.

- #27: Manufacturers, importers and distributers may begin using the new 16-section format SDS (follows the ANSI standard) during the transition from the 1994 Haz Com standard and the final 2012 Haz Com standard but no later than June 1, 2015. They are required to provide a revised copy of the MSDS/SDS to the employer anytime changes are made. Employers are required to maintain copies of all SDSs for the chemicals used and/or stored within the work area. They should have a system to ensure all SDSs are present/accounted and to periodically check for the most current SDS (usually based on revision date) when received from a manufacturer, importer or distributer. The employer is to maintain a copy of the most current SDS and archive prior MSDSs/SDSs. SDSs are to accessible/available to employees.

- #28: Section 1, Identification includes product identifier; manufacturer or distributor name, address, phone number; emergency phone number; recommended use; restrictions on use. Section 2, Hazard(s) identification includes all hazards regarding the chemical; required label elements. Section 3, Composition/information on ingredients includes information on chemical ingredients; trade secret claims. Section 4, First-aid measures includes important symptoms/ effects, acute, delayed; required treatment. Section 5, Fire-fighting measures lists suitable extinguishing techniques, equipment; chemical hazards from fire. Section 6, Accidental release measures lists emergency procedures; protective equipment; proper methods of containment and cleanup.

- #29: Section 7, Handling and storage lists precautions for safe handling and storage, including incompatibilities. Section 8, Exposure controls/personal protection lists OSHA's Permissible Exposure Limits (PELs); Threshold Limit Values (TLVs); appropriate engineering controls; personal protective equipment (PPE). Section 9, Physical and chemical properties lists the chemical's characteristics. Section 10, Stability and reactivity lists chemical stability and possibility of hazardous reactions. Section 11, Toxicological information includes routes of exposure; related symptoms, acute and chronic effects; numerical measures of toxicity.

- #31: MIOSHA Act 154 requires that posters noting the location and receipt of new or revised SDSs be placed in the work area. Act 154 will be revised to be in compliance with GHS/Haz Com changes. This change may take some time to be effective. This slide pictures the posters as they will appear with the anticipated change in wording from MSDS to SDS.

- #32: 29 CFR 1910.1200 The Hazard Communication (HazCom) standard establishes uniform requirements to make sure that the hazards of all chemicals imported into, produced, or used in U.S. workplaces are evaluated, and that this hazard information is transmitted to affected employers and exposed employees. The HazCom standard is different from other OSHA health rules because it covers all hazardous chemicals. The rule also incorporates a “downstream flow of information,” which means that producers of chemicals have the primary responsibility for generating and disseminating information, whereas users of chemicals must obtain the information and transmit it to their employees.

- #33: Employer also required to describe how they will inform employees of the hazards of non-routine tasks (for example, cleaning reactor vessels), and the hazards associated with chemicals in unlabeled pipes.

- #35: The amount of the material to which an individual is exposed to is called the Dose. The dose effects are dependent on the concentration of the material that gets into the body over a period of time, or concentration x time. The response depends on the dose and the effects on the body. This may lead to irritation, illness or death. A high concentration for a short period of time is an acute effect. A continued smaller exposure for a long period of time is a chronic effect.