leveraging machine learning for ML tools and approaches to enhance decision-making, efficiency, or performance in a specific domain.

- 1. Senior Design Project Review-1 Presentation [Leveraging Machine Learning for Predictive Maintenance in Industrial Equipment ] Supervised By: Prof. Swagat Kumar Jena Group No.: B5 Name of the Student(s) with Regd. No.: Praveen Sharma - 2141019272 Prince Kumar - 2141011213 Rahul Kumar Mahto - 2141013045 Lohit Mohanty - 2141013174 Department of Computer Sc. and Engineering Faculty of Engineering &Technology (ITER) Siksha ‘O’ Anusandhan (Deemed to be) University Bhubaneswar, Odisha 1

- 2. Presentation Outline Introduction Project Overview Problem Statement & Motivations Objectives & Expected Impact Background & Related Work/ Literature Review Existing Solutions/Related Work & Their Limitations Improvements Over Existing Solutions Proposed Solution & Architecture System Architecture /Workflow Diagram /Model Diagram /Block Diagram/Schematic Layout Key Components/Features & Modules Algorithms and Methods Used/Technologies, Frameworks, and Tools Used Progress in Implementation Plan & Methodology Summary Bibliography 2

- 3. Introduction Project Overview This project aims to create a predictive maintenance system using machine learning to forecast equipment failures with high accuracy. It focuses on optimizing computational efficiency while maintaining strong predictive performance, reducing downtime, lowering maintenance costs, and improving industrial operations through proactive, data-driven decision-making using IoT sensor data and advanced algorithms. 3

- 4. Introduction Problem Statement & Motivations Problem Statement Design a predictive maintenance system that ensures a balance of performance and computational efficiency by leveraging IoT sensor data and evaluating multiple machine learning models. Motivations •Downtime due to equipment failures is costly and disruptive. •Traditional maintenance strategies are either reactive (run-to-failure) or overly resource-intensive (preventive). •Machine learning and IoT present an opportunity for proactive, cost-effective, and highly accurate maintenance systems. 4

- 5. Introduction Objectives •Compare multiple machine learning models for fault prediction. •Identify the most reliable and cost-effective model. •Use IoT sensor data to provide actionable maintenance insights. Expected Impact •Reduction in downtime and maintenance costs. •More efficient and reliable industrial equipment operations. •Data-driven decision-making for maintenance planning. 5

- 6. Background & Related Work Related Work & Their Limitations Literature Survey •Paper 1: LightGBM achieves high accuracy but is computationally intensive. •Paper 2: Random Forest is reliable but costly in large-scale applications. •Paper 3: CatBoost is efficient for imbalanced data but needs further evaluation. •Paper 4: MCC is underexplored in predictive maintenance systems. Identified Gaps •Existing models do not balance computational efficiency and predictive performance well. •MCC is an underutilized metric for evaluating predictive maintenance models. •Few studies compare models based on Accuracy, F1-Score, and MCC. 6

- 7. Existing Solutions & Their Limitations •Traditional maintenance strategies: Run-to-failure and preventive maintenance. •Machine learning models like LightGBM, Random Forest, and CatBoost have strengths and weaknesses. •Computational efficiency and model reliability are not always balanced. •Existing predictive maintenance models often struggle with handling imbalanced datasets, leading to inaccurate fault detection. •Many current solutions lack real-time integration with IoT sensors, limiting their ability to provide dynamic, on-the-spot maintenance insights. 7

- 8. Proposed Solution & Architecture 1.Data Collection: Sensor data on air temperature, process temperature, rotational speed, torque, and tool wear. 2.Data Preprocessing: Cleaning, checking for imbalance, and feature extraction. 3.Model Evaluation: Comparing Random Forest, XGBoost, LightGBM, and CatBoost. 4.Actionable Insights: Visualizing results to select the best model. 8

- 9. System Architecture/ Workflow Diagram 9

- 10. Key Components/ Features & Modules Key Components 1.Sensor Data Collection – Gathers real-time data on air temperature, process temperature, rotational speed, torque, and tool wear. 2.Data Preprocessing – Cleans data, handles missing values, and balances class distribution. 3.Model Training & Evaluation – Compares machine learning models (Random Forest, XGBoost, LightGBM, CatBoost) using Accuracy, F1-Score, and MCC. Features & Modules •Fault Prediction Module – Uses trained ML models to predict potential failures. •Performance Monitoring Module – Tracks model accuracy and reliability over time. •Visualization Dashboard – Displays real-time sensor data and model predictions for easy decision-making. 10

- 11. Algorithms and Methods Used/ Technologies, Frameworks, and Tools Used Algorithms and Methods Used •Machine Learning Models: Random Forest, XGBoost, LightGBM, CatBoost. •Evaluation Metrics: Accuracy, F1-Score, MCC. Technologies, Frameworks, and Tools Used •Python, Scikit-Learn, TensorFlow, IoT Sensors, Jupyter Notebook. 11

- 12. Progress in Implementation Plan 12

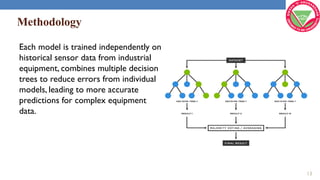

- 13. Methodology Each model is trained independently on historical sensor data from industrial equipment, combines multiple decision trees to reduce errors from individual models, leading to more accurate predictions for complex equipment data. 13

- 14. Summary This project develops a machine learning-based predictive maintenance system to reduce industrial equipment failures and downtime. Using IoT sensor data, models like Random Forest, XGBoost, LightGBM, and CatBoost are evaluated for reliability and cost-effectiveness. LightGBM excels in fault detection, Random Forest ensures consistency, and CatBoost is the most efficient. The system enhances proactive maintenance, reducing costs and improving efficiency. Future work includes real-time IoT integration and model optimization. 14

- 15. Bibliography 1. Ni, F., Zang, H. & Qiao, Y. (2024). Smartfix: Leveraging Machine Learning for Proactive Equipment Maintenance in Industry 4.0. 2. Vago, N.O.P., Forbicini, F. & Fraternali, P. (2024). Predicting Machine Failures from Multivariate Time Series: An Industrial Case Study. 3. Chandu, H.S. (2024). Enhancing Manufacturing Efficiency: Predictive Maintenance Models Utilizing IoT Sensor Data. 4. Arunkumar, G. (2024). AI-Based Predictive Maintenance Strategies for Electrical Equipment and Power Networks.

- 16. 16

![Senior Design Project

Review-1 Presentation

[Leveraging Machine Learning for Predictive

Maintenance in Industrial Equipment ]

Supervised By: Prof. Swagat Kumar Jena

Group No.: B5

Name of the Student(s) with Regd. No.:

Praveen Sharma - 2141019272

Prince Kumar - 2141011213

Rahul Kumar Mahto - 2141013045

Lohit Mohanty - 2141013174

Department of Computer Sc. and

Engineering

Faculty of Engineering &Technology (ITER)

Siksha ‘O’ Anusandhan (Deemed to be) University

Bhubaneswar, Odisha

1](https://image.slidesharecdn.com/b5review-1-250413191302-d276f7bd/85/leveraging-machine-learning-for-ML-tools-and-approaches-to-enhance-decision-making-efficiency-or-performance-in-a-specific-domain-1-320.jpg)