Programmable_Logic_Controllers_Introduction_to_PLCs__(Chapter_1)_Lec1.ppt

- 1. 1 Faculty of Engineering & Information Technology Al-AZHAR UNIVERSITY Programmable Logic Controllers ( ITCE 5319 ) Introduction to PLCs (Chapter 1) Instructor: Eng. Mohammad Aqel Second Semester, 2007/2008

- 2. 2 What is a PLC? • Is a microprocessor base controller that uses a programmable memory to store instructions and to implement functions such as logic, timing, counting in order to control machines . • Input devices, e.g. sensors such as switches, and output devices in the system being controlled, e.g. motor, valves, etc., are connected to the PLC. • The operator enters a sequence of instructions e.g. ladder logic diagram. The program then is downloaded into the memory of the PLC. The controller monitors the inputs’ status and outputs’ status according to this program and carries out the control rules for which it has been programmed.

- 3. 3 • In a traditional industrial control system, all control devices are wired directly to each other . In a PLC system, however, the PLC replaces the wiring between the devices. • Instead of being wired directly to each other, all equipment is wired to the PLC. Then, the control program inside the PLC provides the "wiring" connection between the devices. • The control program is the computer program stored in the PLC’s memory that tells the PLC what’s supposed to be going on in the system. • The use of a PLC to provide the wiring connections between system devices is called softwiring.

- 4. 4 WHY USE PLCS? • Softwiring makes changes in the control system easy and cheap. • If you want a device in a PLC system to behave differently or to control a different process element, all you have to do is change the control program. In a traditional system, making this type of change would involve physically changing the wiring between the devices. • Flexibility: software based system • Compact: replace hundreds of relays, timers and counters • Reliable: less mechanical parts • reduced costs

- 5. 5 BUT WHAT EXACTLY IS A PLC? A PLC basically consists of two elements: • the central processing unit (CPU) • the input/output (I/O) system

- 6. 6 The Central Processing Unit • is the part of a programmable controller that retrieves, decodes, stores, and processes information. • It also executes the control program stored in the PLC’s memory. • In essence, the CPU is the "brains" of a programmable controller.

- 7. 7 The CPU has three parts: • the processor • the memory system • the power supply • The processor is the section of the CPU that codes, decodes, and computes data. • The memory system is the section of the CPU that stores both the control program and data from the equipment connected to the PLC. • The power supply is the section that provides the PLC with the voltage and current it needs to operate.

- 8. 8 The Input/Output System • The input/output unit provides the interface between the system and the outside world, allowing for connections to be made through input/output channels to input devices and output devices • Every input and output point has a unique I/O address which can be recognized by the CPU. • If the CPU can be thought of as the brains of a PLC, then the I/O system can be thought of as the arms and legs.

- 9. 9 A LITTLE MORE ABOUT INPUTS AND OUTPUTS All of the field devices connected to a PLC can be classified in one of two categories: • inputs • outputs • Inputs are devices that supply a signal/data to a PLC. Typical examples of inputs are push buttons, switches, and measurement de-vices. • Outputs are devices that await a signal/data from the PLC to perform their control functions. Lights, horns, motors, and valves

- 10. 10 • There are two basic types of input and output devices: • discrete • analog • Discrete devices are inputs and outputs that have only two states: on and off. A 1 means that the device is on and a 0 means that the device is off. • Analog devices are inputs and outputs that can have an infinite number of states. These devices can not only be on and off, but they can also be barely on, almost totally on, not quite off, etc.

- 11. 11 AND A LITTLE MORE ABOUT THE CONTROL PROGRAM • The control program is a software program in the PLC’s memory. • The control program is made up of things called instructions. • Instructions are little computer codes that make the inputs and outputs as what you want the result, such as (add and subtract data, time and count events, compare information, etc.). • remember, changing the system is a snap (fast). If you want the system to act differently, just change the instructions in the control program. • all PLCs use two basic types of instructions: • contacts • coils

- 12. 12 Contacts & Coils • Contacts are instructions that refer to the input conditions to the control program—that is, to the information supplied by the input field devices . • The contact waits for the input to do something in particular (e.g., turn on, turn off). • Coils are instructions that refer to the outputs of the control program to what each particular output device is supposed to do in the system.

- 13. 13 Ladder Logic • Ladder logic is the main programming method used for PLCs. • ladder logic has been developed to mimic (like) relay logic. • By selecting ladder logic as the main programming method, the amount of retraining needed for engineers and tradespeople was greatly reduced. • A relay is a simple device that uses a magnetic field to control a switch, as pictured in next slide.

- 14. 14 normally open normally closed input coil OR OR •The contact that closes when the coil is energized is called normally open. •The normally closed contacts touch when the input coil is not energized. •Relays are normally drawn in schematic form using a circle to represent the input coil. The output contacts are shown with two parallel lines. •Normally open contacts are shown as two lines, Normally closed contacts are shown with two lines with a diagonal line through them.

- 15. 15 Example of a Relay 115V AC wallplug relaylogic input A (normally closed) input B (normally open) output C (normally open) ladder logic A B C •The first relay on the left is used as normally closed, and will allow current to flow until a voltage is applied to the input A. •The second relay is normally open and will not allow current to flow until a voltage is applied to the input B. •If current is flowing through the first two relays then current will flow through the coil in the third relay, and close the switch for output C. •Ladder logic form, This can be read logically as C will be on if A is off and B is on.

- 16. 16 Relay Logic In PLC ladder power supply +24V com. inputs outputs push buttons logic PLC AC power 115V a c neut. A B C light

- 17. 17 A Seal-in Circuit • Many relays also have multiple outputs and this allows an output relay to also be an input simultaneously. • The input B will only be on when the output B is on. If B is off, and A is energized, then B will turn on.

- 18. 18 Reading Ladder Logic HOT NEUTRAL INPUTS OUTPUTS A B X C D E F G H Y Note:Power needs to flow through some combination of the inputs (A,B,C,D,E,F,G,H) to turn on outputs (X,Y). • In the figure there are two rungs, and on each rung there are combinations of inputs (two vertical lines) and outputs (circles). • If the inputs are opened or closed in the right combination the power can flow from the hot rail, through the inputs, to power the outputs, and finally to the neutral rail. •In the top rung the contacts are normally open and normally closed. Which means if input A is on and input B is off, then power will flow through the output and activate it. Any other combination of input values will result in the output X being off. • The second rung of Figure is more complex, there are actually multiple combinations of inputs that will result in the output Y turning on.

- 19. 19 Mnemonics • This is other method for programming PLCs. • An example of mnemonics is shown in Figure. In this example the instructions are read one line at a time from top to bottom.

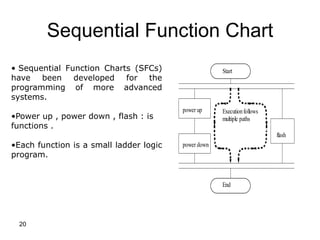

- 20. 20 Sequential Function Chart Start End power up power down flash Executionfollows multiple paths • Sequential Function Charts (SFCs) have been developed for the programming of more advanced systems. •Power up , power down , flash : is functions . •Each function is a small ladder logic program.

- 21. 21 PLC Connections • When a process is controlled by a PLC it uses inputs from sensors to make decisions and update outputs to drive actuators, as shown in Figure below. • The control loop is a continuous cycle of the PLC reading inputs, solving the ladder logic, and then changing the outputs. •When power is turned on initially the PLC does a quick check to ensure that the hardware is working properly. •If there is a problem the PLC will halt and indicate there is an error. For example, if the PLC backup battery is low and power was lost, the memory will be corrupt

- 22. 22 CASE STUDY • Problem: Try to develop a ladder logic diagram that will allow three switches in a room to control a single light. ?

- 23. 23 Solution1 • Solution: There are two possible approaches to this problem. The first assumes that any one of the switches on will turn on the light, but all three switches must be off for the light to be off.

- 24. 24 Solution2 • The second solution assumes that each switch can turn the light on or off, regardless of the states of the other switches. • This method is more complex and involves thinking through all of the possible combinations of switch positions.

- 25. 25 Summary • Normally open and closed contacts. • Relays and their relationship to ladder logic. • PLC outputs can be inputs, as shown by the seal in circuit. • Programming can be done with ladder logic, mnemonics, SFCs. • There are multiple ways to write a PLC program.

- 26. 26 ASSIGNMENT PROBLEM • Develop a simple ladder logic program that will turn on an output X if inputs A and B, or input C is on.