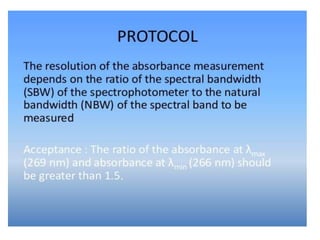

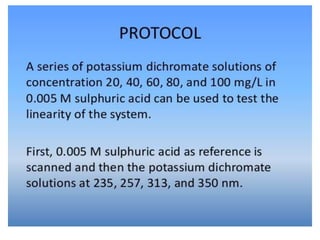

The document discusses the qualification process for UV-Visible spectrophotometers. Qualification ensures instruments are suitable for their intended use and will function properly over time. It involves design, installation, operational, and performance qualification. For a UV-Vis spectrophotometer, key parameters that must be qualified include wavelength accuracy and precision, stray light, resolution, noise, baseline flatness, stability, photometric accuracy, and linearity. The document provides testing protocols for checking each parameter.